What Does Plant Conveyors And Systems Mean?

Table of ContentsThe Of Plant Conveyors And Systems10 Simple Techniques For Plant Conveyors And SystemsHow Plant Conveyors And Systems can Save You Time, Stress, and Money.Some Known Facts About Plant Conveyors And Systems.An Unbiased View of Plant Conveyors And SystemsLittle Known Facts About Plant Conveyors And Systems.Top Guidelines Of Plant Conveyors And SystemsThe Best Strategy To Use For Plant Conveyors And Systems

Issues with belt tracking can be caused by misuse of the conveyor, its atmosphere, and poor maintenance. Pneumatic Stress Many conveying systems have pneumatically-driven elements.

555(a)( 3 ): Emergency quit switches avoid resurgence of the system up until the emergency situation button is reset to "ON". 555(a)( 4 ): Protective treatments as well as security on screw conveyors are needed. 555(a)( 5 ): Expenses conveyors have to have protective coverings listed below the conveyor.

Some Known Factual Statements About Plant Conveyors And Systems

0-2020, which covers the secure use equipment and also consists of different security devices that ought to be component of the installation as well as building procedure. ASME B20. 1-2018: ASME B20. 1 -2018 includes the needs for the design, building and construction, upkeep, and also procedure of a sharing system pertaining to threats. It is a collection of basic security guidelines.

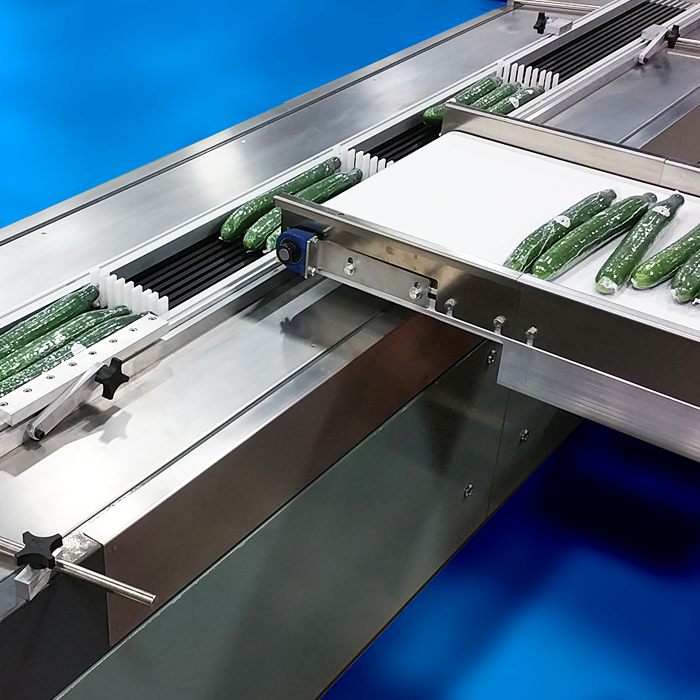

Industrial conveyor systems can be located practically anywhere virtually all manufacturing as well as handling markets need a safe, trusted, automatic way of carrying products or products from one area to one more within the same manufacturing facility. No matter if the item concerned is ground coffee or an automobile chassis material taking care of systems are a vital part of manufacturing (Plant Conveyors and Systems).

These will certainly identify what sort of communicating is finest fit for your manufacturing procedures. Each conveyor includes its very own collection of pros as well as cons that you have to carefully consider prior to making the final choice. Right here are 7 fundamental kinds of commercial conveyors and also what you can anticipate from them.

The 10-Second Trick For Plant Conveyors And Systems

At the very same time, if product integrity is not of significance (such as in transporting waste), augers have couple of relocating parts and are easy to keep and also tidy. The structure of an aero-mechanical system is the generation of a centrifugal force. This type of conveyor consists of a tube (normally made from steel) with an inside distributing rope.

Probably the most usual kind of conveyors, belt conveyor systems, have actually found their rightful place in practically every market. This system features pulley-blocks (two or more) as well as a closed-loop (the conveyor belt) that rotates around them. Several sheaves in the system can be powered, moving the belt in the best instructions.

You can see them at flight terminals, transporting luggage, at dining establishments, moving food (specifically sushi restaurants), at ski facilities, delivering people and also their ski devices, as well as a lot more. A belt conveyor can be enclosed to stop contamination and loss of material, yet likewise be open if it belongs to production line - Plant Conveyors and Systems.

The 45-Second Trick For Plant Conveyors And Systems

As their name recommends, chain conveyors utilize an unlimited chain to carry material down a manufacturing line. The chain runs over sprockets at each end of the line, and it can have unique add-ons. The most typical application for chain conveyors is the movement of hefty lots bulky materials that are really wide or long (or both), such as commercial containers, grid boxes, and also pallets.

Wire conveyors can relocate material in any type of instructions you require up and down, horizontally, at angles, and around edges. They have reduced power expenses since they work on motors of 7. 5HP or much less. These systems are additionally reasonably easy to maintain because they have detachable conveyor elements. The core feature of tubular wire conveyors is that they are exceptionally mild on the products.

Take right into account the dimension as well as elevation of the system compared to the flooring area of your facility, as well as the type of material you desire to be shared. Loosened product? While click to read there are many various kinds of conveyor systems, they typically are composed of a framework that sustains either rollers, wheels, or a belt, upon which materials relocate from one place to one more.

The conveyor belting is supported by either a steel slider pan for light lots where no friction would certainly be applied to the belt to create drag or on rollers. Power is supplied by electric motors that utilize either variable or consistent rate reduction equipments. The belts themselves can be made from countless materials, which should match to the problems under which the belt will be operating.

Transporting a heavier load indicates a thicker and more powerful building of conveyor belting product is required. Belt conveyors are commonly powered and Bonuses also can be operated at different speeds depending upon the throughput called for. The conveyors can be operated flat or can be inclined also. Belt conveyors can be troughed for bulk or huge products.

The Basic Principles Of Plant Conveyors And Systems

Key specs include the roller size and also axle center measurements. The rollers are not powered and make use of gravity, if inclined, to move the item, or by hand if mounted flat.

Cord conveyors can relocate material in any instructions you require up and down, flat, at angles, and around edges. These systems are additionally reasonably simple to preserve due to the fact that they have removable conveyor parts.

Take right into account the dimension and also elevation of the system compared to the floor room of your center, as well as the type of material you want to be communicated. Loose material? While there are numerous different kinds of conveyor systems, they normally consist of a structure that Check Out Your URL supports either rollers, wheels, or a belt, upon which products move from one location to an additional.

The conveyor belting is supported by either a metal slider pan for light tons where no friction would be put on the belt to cause drag or on rollers. Power is offered by electric motors that make use of either variable or consistent rate reduction equipments. The belts themselves can be made from various materials, which must represent the conditions under which the belt will certainly be running.

Delivering a heavier lots suggests a thicker and also more powerful construction of conveyor belting material is called for. Belt conveyors are typically powered as well as can be operated at numerous speeds depending on the throughput called for. The conveyors can be operated flat or can be inclined also. Belt conveyors can be troughed for bulk or big products.

Getting My Plant Conveyors And Systems To Work

Secret specifications consist of the roller size as well as axle facility measurements. Roller conveyors are utilized primarily in material handling applications such as on loading anchors, for luggage handling, or on assembly lines among many others. The rollers are not powered and also make use of gravity, if inclined, to move the item, or manually if installed horizontally.